A collection of training videos & tutorials.

Find the right wax for the right conditions.

Racing wax for Snowboarding & Skiing.

Use the same tools the pro’s use.

Base Structure Theory

Before you sharpen edges or wax...

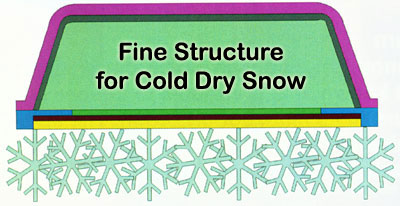

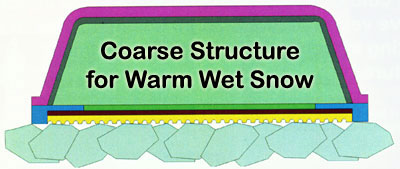

- Like treads on a tire, ski bases need structure reduce drag (see below).

- Your skis need to ride on a film of water produced from the friction of your base and edges cutting through the snow.

- In cold, dry snow the structure should be fine and shaped to hold water a little longer under your ski since so little is available under these conditions.

- On cold crystalline snow, the ski base should be as smooth as possible so the points of friction are minimized.

- On amorphous, wet snow, a coarser structured ski base is better to minimize the points of friction. Pockets of air between the ski base and the snow means that water is repelled from the ski base reducing the braking effect (like a beer glass sliding on a bar -if your below 21, watch a cowboy movie- a flat-bottomed glass won't slide as well as one with an air pocket).

- In warm, wet snow the idea is to move the water away from the base and reduce suction.

When to grind race skis...

- At the beginning of the season each ski should be prepared for the race conditions expected at the season's start.

- New skis tend to have a medium to coarse structure that is ideal for wetter snow, but not dry snow. Consult with a coach or local race shop to learn what structure is running best in your region.

- In season, grind when drastic changes in snow are expected (dry to wet and vice versa).

- Early Spring, prepare the skis for late season wet snow conditions.

Base Structure

General Advice

- Don't belt grind race skis. Belt grinding is not the same as stone grinding. A belt grind will not produce a flat base.

- Before experimenting with new grinds, have someone test its performance.

- Stonegound skis will run slower after this process. Don't ski on the skis as returned from the shop, you will need hot boxing or several days of waxings before they hit the snow; follow the process below.

- The idea is to have your bases professionally structured by stone grinding and maintain them as long as possible; your skis will get faster as your wax cycles increase.

- Terminology: More depth/width in a structure is considered more "aggressive"; a shallower, tighter structure is less aggressive.

- A coarser structure is hard to turn; the ski wants to track more.

- Only for wet/warm conditions should you be able to feel the structure under your fingers. Otherwise, in cold/dry conditions, you want a structure that you can see, but not feel with your fingers.

- In dry conditions, you want to hold water under the ski, so a structure that is finer on the outside than in the middle will help achieve this.

- Keep in mind that even if the temperature is high, a course that has been chemically treated will have harder snow and a fine structure should be used.

- Take into account the speed of the event. The faster a ski goes (GS vs. Slalom) the more heat and water will be produced. The coarseness of the structure should increase as the speed of the event increases.

- The arrow/chevron structure is more important for Nordic than Alpine; it has a smaller range.

- Different structures can be laid over each other to break up the repetitiveness of the structure.

- The broken pattern is used to break up the free water running through the structure and reduce suction. If a constant pattern is used, the free water will start to follow the pattern and lose its effectiveness.

- Find an expert in your area for advice on what structure is running best for the local conditions.

- The structure on a freshly ground ski needs to be "de-fanged", meaning the new structure can have high points (like the points of a pyramid) that should be removed. This is done with the pads sold here or by waxing and scraping.

- Wet/warm - Use a big thick cross structure with a deep cut. Since the humidity is high, this works best by wicking away the moisture from the board. After waxing, use a good hard (brass) brush down the board, then at 45 degree angles both ways across the board. Opening up the structure is key, so brush until no wax remains in the structure. Also, when using the powders at this temperature, buff the powder, and then use a nylon or horsehair to remove the excess.

- A board's base is wide and the key is to move water out efficiently.

- Dry/cold - For cold/dry conditions, stick with a thin linear structure. Brush well, usually with a cold harder wax, getting deep isn't as important.

- Here the idea is to keep water under the board. You need a thin film of water for speed.

- Remove any wax that the shop laid down. The process below removes micro hairs from the surface of a freshly ground base.

- Use the gray fibertex pad from the 3-pad fibertex set, with a brush over it (you're pressing on the brush to get even pressure for the pad underneath that is touching the base).

- Go over it about 50 times in both directions.

- Change to the red/brown fibertex pad and repeat 50 times.

- Wax, cool, scrape at least 3 times (5 is better) before the skis touch the snow. If you are a racer, you should consider repeating this 10-15 times before the ski touches the snow. On the World Cup circuit, the waxing cycles go up to 30 to 50 times before hitting the snow!

- With each wax cycle heat the base surface as little as possible. The idea is to lift and stiffen base micro hairs so they can be cut away with the scraper.

- NOTE 1: Run 5-6 times with re-waxing between runs before they are considered training quality.

- NOTE 2: Run 10 times with 10-15 waxings for racing quality.

- NOTE 3: Keep the bases waxed for best performance.

Tuning Tips

- Wax Wizard

- Tuning Tips

- Tuning Tips Overview

- Quick Tuning Guide

- Base Structure Theory

- Edge Tuning

- Ptex Base Repair

- Diamond Stone Care & Use

- Sidewall Cutting

- Wax Application

- Wax Iron Setting

- Choosing Wax

- Wax Charts

- Choosing Tuning Kits

- Tuning Kit Instructions

- Essential Equipment List

- Powder Application

- New Skis/Board Care

- Spring Tuneup

- Summer Storage

- Buying at Ski Swap Sales

- Questions and Answers

- Video Archive Overview

- Newsletter Signup